SP-17 Rapid Patch Liquid

SP-17

Product Overview

Uses

Preparation

The data below represents the most pertinent information needed by a professional installer to understand and efficiently install this material. The data was gathered at temperatures of 72-75 F and 30-50% RH. A wide array of independent and company test data has been compiled on this product but is too large to place on this Technical Data Sheet. Please direct inquiries for detailed test reports on this product to lab@polymernation.com.

SP-17

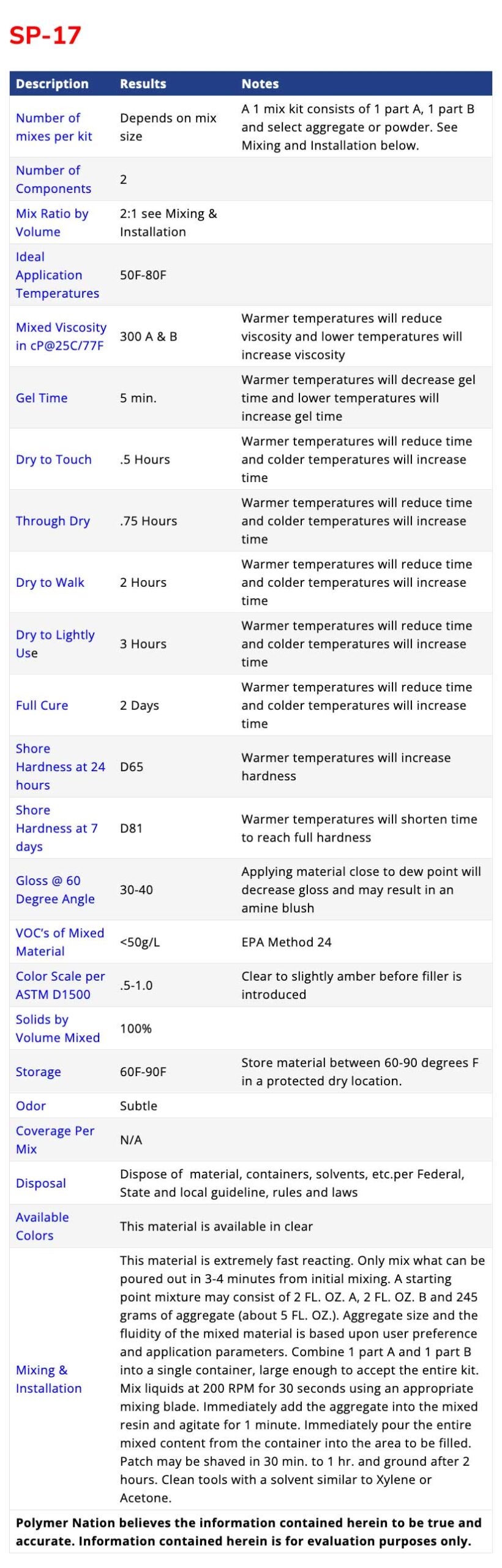

| Description | Results | Notes |

| Number of mixes per kit | Depends on mix size | A 1 mix kit consists of 1 part A, 1 part B and select aggregate or powder. See Mixing and Installation below. |

| Number of Components | 2 | |

| Mix Ratio by Volume | 2:1 see Mixing & Installation | |

| Ideal Application Temperatures | 50F-80F | |

| Mixed Viscosity in cP@25C/77F | 300 A & B | Warmer temperatures will reduce viscosity and lower temperatures will increase viscosity |

| Gel Time | 5 min. | Warmer temperatures will decrease gel time and lower temperatures will increase gel time |

| Dry to Touch | .5 Hours | Warmer temperatures will reduce time and colder temperatures will increase time |

| Through Dry | .75 Hours | Warmer temperatures will reduce time and colder temperatures will increase time |

| Dry to Walk | 2 Hours | Warmer temperatures will reduce time and colder temperatures will increase time |

| Dry to Lightly Use | 3 Hours | Warmer temperatures will reduce time and colder temperatures will increase time |

| Full Cure | 2 Days | Warmer temperatures will reduce time and colder temperatures will increase time |

| Shore Hardness at 24 hours | D65 | Warmer temperatures will increase hardness |

| Shore Hardness at 7 days | D81 | Warmer temperatures will shorten time to reach full hardness |

| Gloss @ 60 Degree Angle | 30-40 | Applying material close to dew point will decrease gloss and may result in an amine blush |

| VOC’s of Mixed Material | <50g/L | EPA Method 24 |

| Color Scale per ASTM D1500 | .5-1.0 | Clear to slightly amber before filler is introduced |

| Solids by Volume Mixed | 100% | |

| Storage | 60F-90F | Store material between 60-90 degrees F in a protected dry location. |

| Odor | Subtle | |

| Coverage Per Mix | N/A | |

| Disposal | Dispose of material, containers, solvents, etc.per Federal, State and local guideline, rules and laws | |

| Available Colors | This material is available in clear | |

| Mixing & Installation | This material is extremely fast reacting. Only mix what can be poured out in 3-4 minutes from initial mixing. A starting point mixture may consist of 2 FL. OZ. A, 2 FL. OZ. B and 245 grams of aggregate (about 5 FL. OZ.). Aggregate size and the fluidity of the mixed material is based upon user preference and application parameters. Combine 1 part A and 1 part B into a single container, large enough to accept the entire kit. Mix liquids at 200 RPM for 30 seconds using an appropriate mixing blade. Immediately add the aggregate into the mixed resin and agitate for 1 minute. Immediately pour the entire mixed content from the container into the area to be filled. Patch may be shaved in 30 min. to 1 hr. and ground after 2 hours. Clean tools with a solvent similar to Xylene or Acetone. | |

| Polymer Nation believes the information contained herein to be true and accurate. Information contained herein is for evaluation purposes only. |

||