F-52 SL 50 Urethane Concrete Slurry Overlay

F-52 SL 50

Product Overview

Uses

Preparation

The data below represents the most pertinent information needed by a professional installer to understand and efficiently install this material. The data was gathered at temperatures of 72-75 F and 30-50% RH. A wide array of independent and company test data has been compiled on this product but is too large to place on this Technical Data Sheet. Please direct inquiries for detailed test reports on this product to lab@polymernation.com.

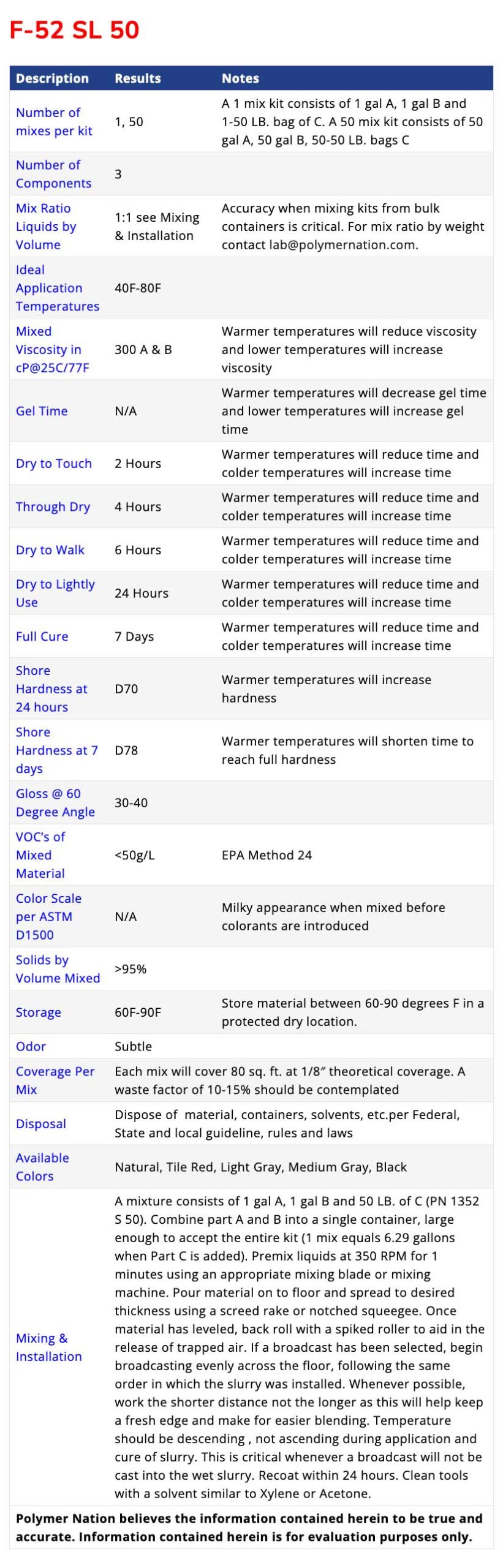

F-52 SL 50

| Description | Results | Notes |

| Number of mixes per kit | 1, 50 | A 1 mix kit consists of 1 gal A, 1 gal B and 1-50 LB. bag of C. A 50 mix kit consists of 50 gal A, 50 gal B, 50-50 LB. bags C |

| Number of Components | 3 | |

| Mix Ratio Liquids by Volume | 1:1 see Mixing & Installation | Accuracy when mixing kits from bulk containers is critical. For mix ratio by weight contact lab@polymernation.com. |

| Ideal Application Temperatures | 40F-80F | |

| Mixed Viscosity in cP@25C/77F | 300 A & B | Warmer temperatures will reduce viscosity and lower temperatures will increase viscosity |

| Gel Time | N/A | Warmer temperatures will decrease gel time and lower temperatures will increase gel time |

| Dry to Touch | 2 Hours | Warmer temperatures will reduce time and colder temperatures will increase time |

| Through Dry | 4 Hours | Warmer temperatures will reduce time and colder temperatures will increase time |

| Dry to Walk | 6 Hours | Warmer temperatures will reduce time and colder temperatures will increase time |

| Dry to Lightly Use | 24 Hours | Warmer temperatures will reduce time and colder temperatures will increase time |

| Full Cure | 7 Days | Warmer temperatures will reduce time and colder temperatures will increase time |

| Shore Hardness at 24 hours | D70 | Warmer temperatures will increase hardness |

| Shore Hardness at 7 days | D78 | Warmer temperatures will shorten time to reach full hardness |

| Gloss @ 60 Degree Angle | 30-40 | |

| VOC’s of Mixed Material | <50g/L | EPA Method 24 |

| Color Scale per ASTM D1500 | N/A | Milky appearance when mixed before colorants are introduced |

| Solids by Volume Mixed | >95% | |

| Storage | 60F-90F | Store material between 60-90 degrees F in a protected dry location. |

| Odor | Subtle | |

| Coverage Per Mix | Each mix will cover 80 sq. ft. at 1/8″ theoretical coverage. A waste factor of 10-15% should be contemplated | |

| Disposal | Dispose of material, containers, solvents, etc.per Federal, State and local guideline, rules and laws | |

| Available Colors | Natural, Tile Red, Light Gray, Medium Gray, Black | |

| Mixing & Installation | A mixture consists of 1 gal A, 1 gal B and 50 LB. of C (PN 1352 S 50). Combine part A and B into a single container, large enough to accept the entire kit (1 mix equals 6.29 gallons when Part C is added). Premix liquids at 350 RPM for 1 minutes using an appropriate mixing blade or mixing machine. Pour material on to floor and spread to desired thickness using a screed rake or notched squeegee. Once material has leveled, back roll with a spiked roller to aid in the release of trapped air. If a broadcast has been selected, begin broadcasting evenly across the floor, following the same order in which the slurry was installed. Whenever possible, work the shorter distance not the longer as this will help keep a fresh edge and make for easier blending. Temperature should be descending , not ascending during application and cure of slurry. This is critical whenever a broadcast will not be cast into the wet slurry. Recoat within 24 hours. Clean tools with a solvent similar to Xylene or Acetone. | |

| Polymer Nation believes the information contained herein to be true and accurate. Information contained herein is for evaluation purposes only. |

||